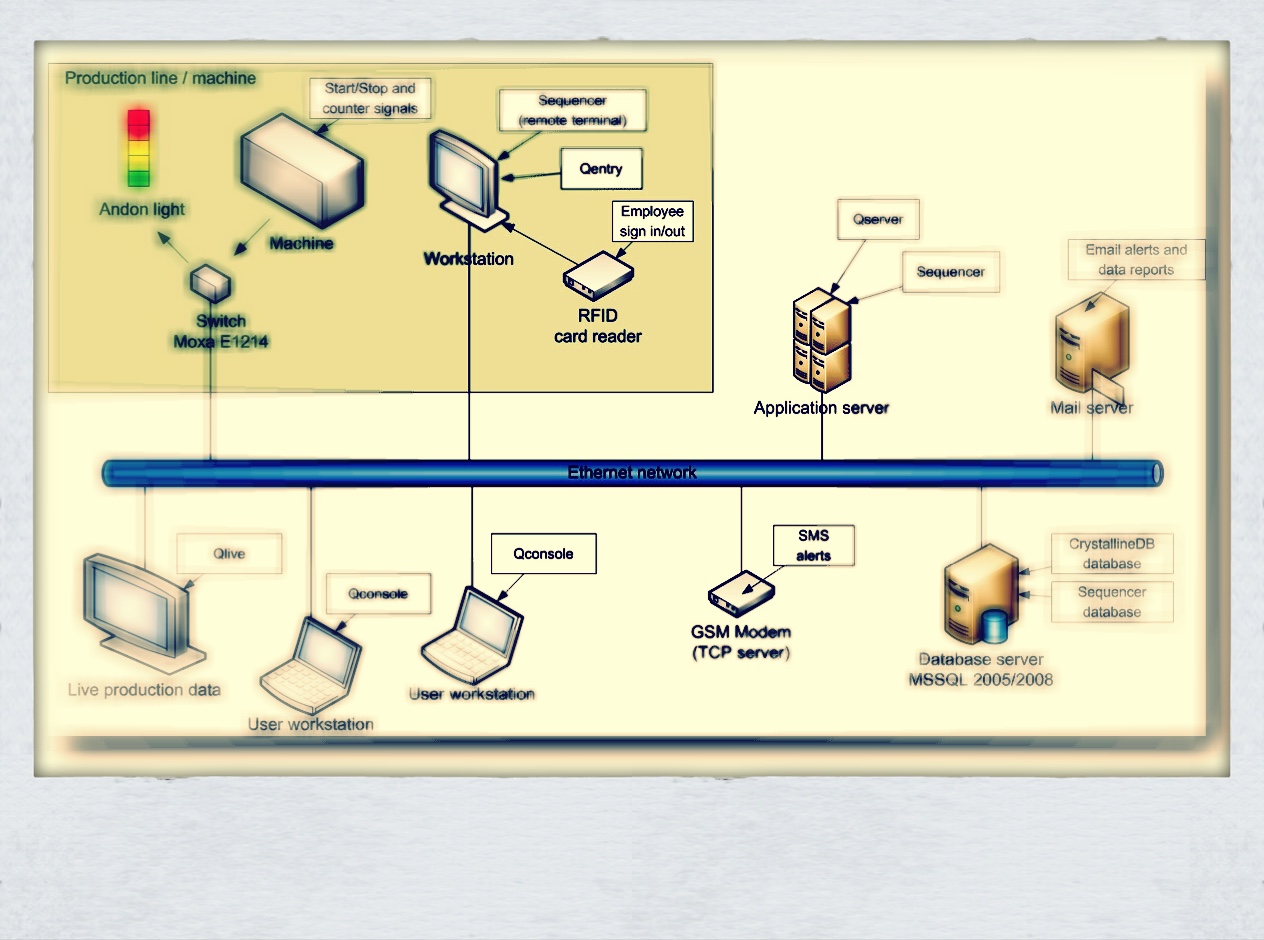

With regard to big… and small factories

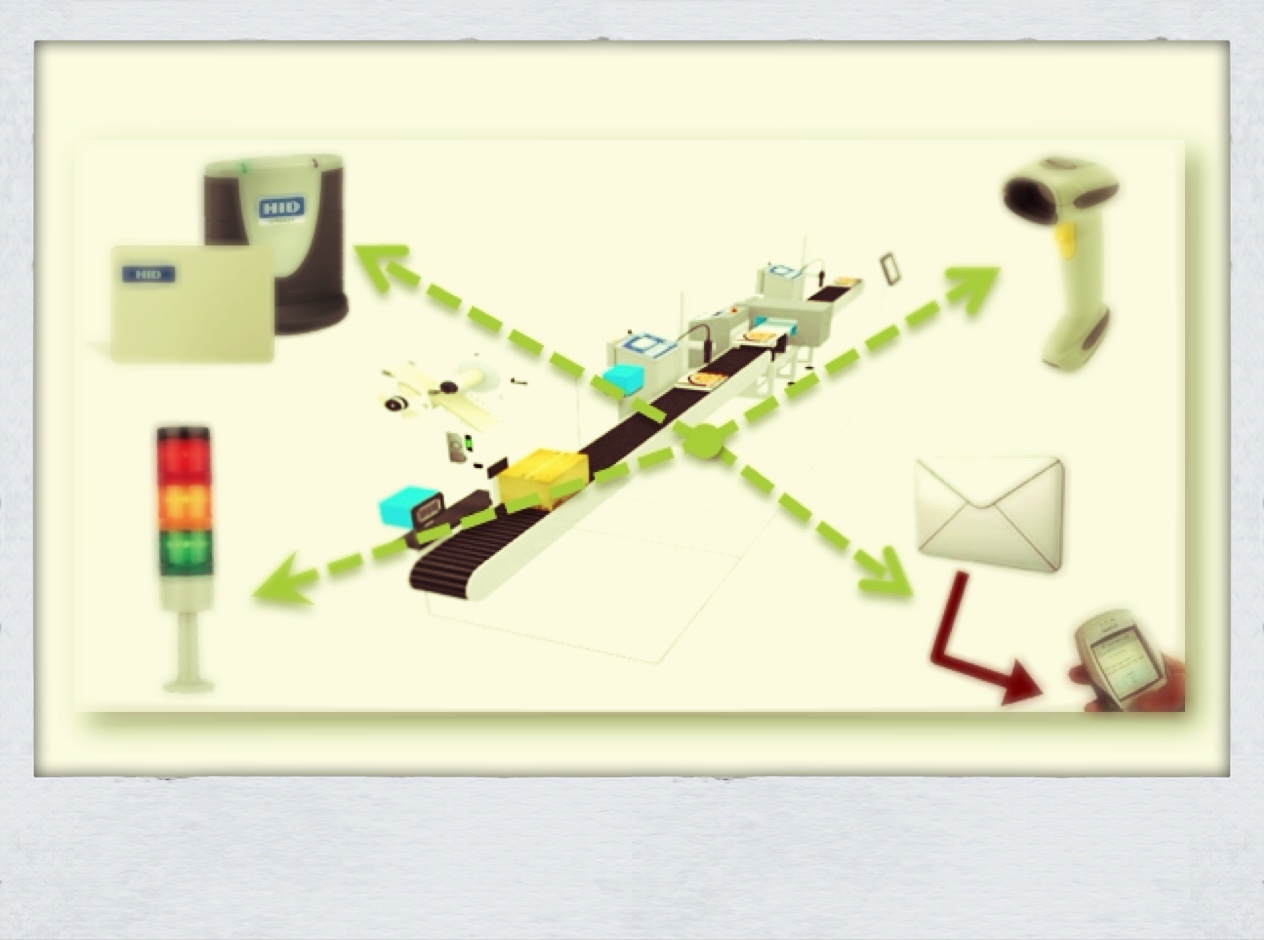

Our solutions are innovative on a global scale, but we are also open to target smaller customers. Our system is available in three main options:

- Basic — a budget option for customers who are satisfied with basic Crystalline functionalities.

- Plus — an option created for customers who need more functions, including the production monitoring in real time and sudden events notifications.

- Pro — an option for customers who want to fully exploit all system functionalities, including the complete machine and production lines data transfer automation.