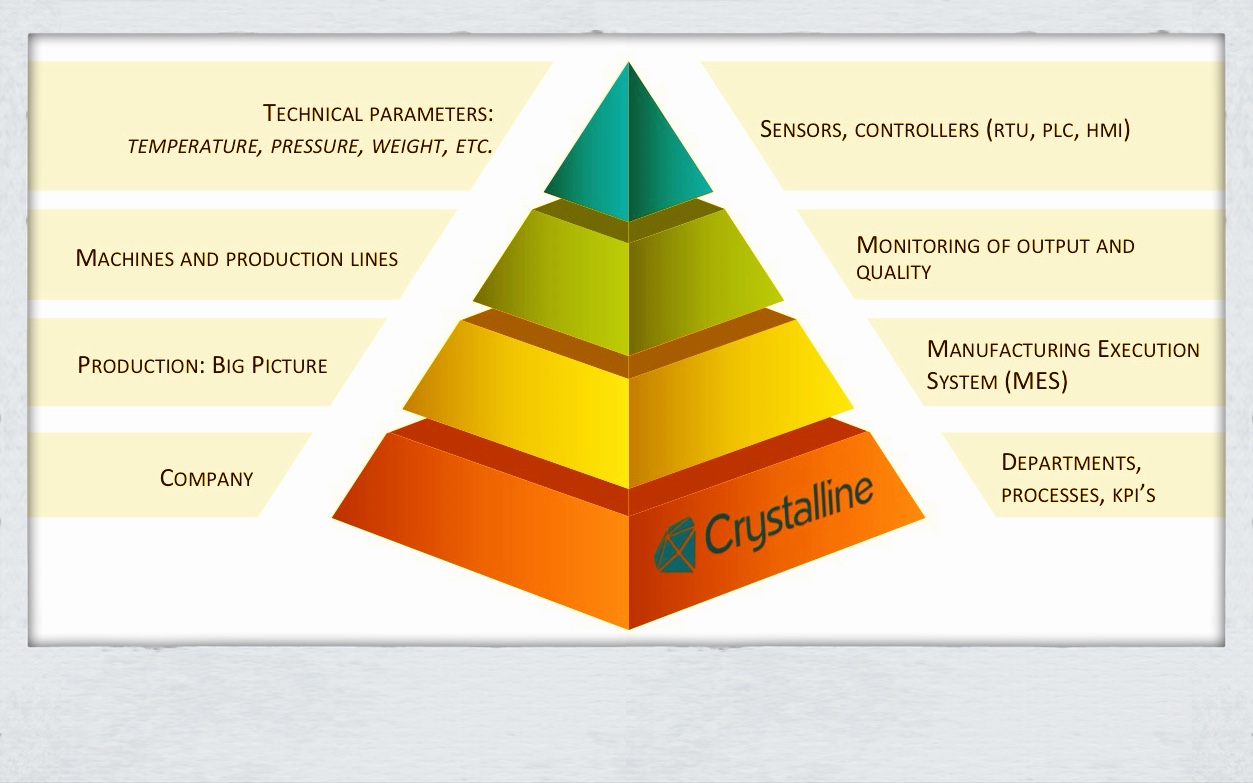

Designed by production optimization experts

One of Crystalline’s creators and founders is Marcin Gołąbek – LSS Master Black Belt and expert in improvement and “rescuing” of manufacturing companies. Many years spent at several customer locations around the globe, both large global corporations and smaller local manufacturers, have helped him to understand customers’ needs regarding production monitoring, control, and analyses. It turns out that, regardless of the factory’s size, industry sector, or location, many problems are common for all companies. These aspects served as a common basis while creating Crystalline. We believe that flexibility, which is the basis for our system, makes it suitable for every factory in the world.

Special attention should be paid to the tools and techniques used in reporting and notifying functionalities. Many solutions are based on advanced methodologies: Six Sigma, Lean Manufacturing, and Theory of Constraints (TOC).

That is why we can be sure that our solution is compatible with what large factories have been dealing with for years. Our customers can catch up with the leaders and never lag behind.